Mechanical Operations Laboratory

Mechanical Operations Laboratory involves handling and processing of particulate solids which form the major components of production processes in Chemical industries like Cement, Fertilizer, Paint and Pharmaceuticals, etc. The laboratory is well equipped with sophisticated units for size reduction and size separation operations.

Equipments: Plate and Frame Filter Press Setup, Leaf filter Setup, Jaw Crusher Setup, Roll Crusher Setup, Sedimentation Jar Studies Apparatus, Cyclone Separator Setup, Ball Mill, Sieve Shaker, Air Elutriator

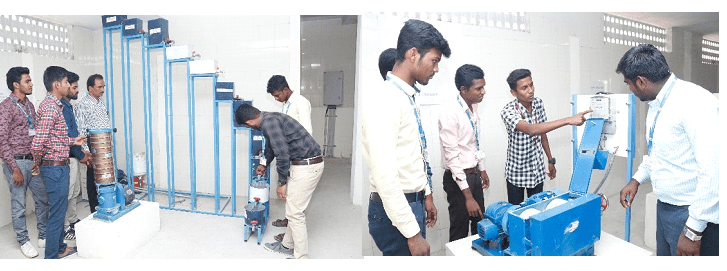

Fluid Mechanics Laboratory

Fluid Mechanics laboratory is important in the Chemical Engineering curriculum, since in any process industry, storage, handling, and transportation of fluids play a vital role. Chemical Engineers are concerned with transportation of fluids (both liquids and gases) from one location to another through pipes or ducts. This activity requires determination of the pressure drop, friction factor through the system and consequently of the power required for pumping, selection of suitable type of pumping device and measurement of the flow rates.

Equipments: Venturi meter, Orifice meter, Rotameter, Pipes and fittings, Helical and spiral coils, Centrifugal pump, Packed column, Fluidized bed, Reciprocating pump, Viscometer

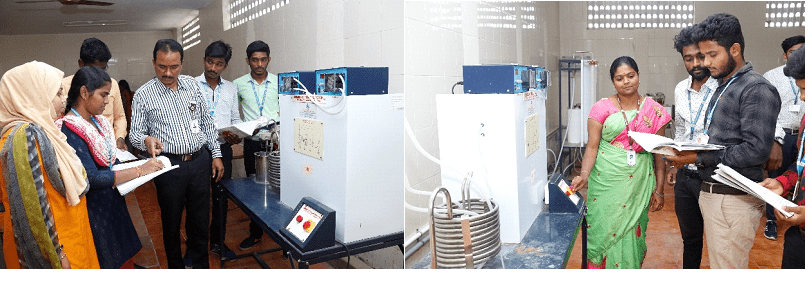

Heat Transfer Laboratory

The lab provides practical knowledge on three basic modes of heat transfer and their applications in industrial heat transfer operations. Experiments help the students to gain practical experience on various heating/cooling mechanisms to understand the principles of thermo-fluid/solid sciences.

Equipments:Vertical and Horizontal Condenser, Shell and Tube heat exchanger, Natural Convention Apparatus, Forced Convention Apparatus, Double pipe heat exchanger, Pin-Fin Apparatus, Lagged pipe Apparatus

Mass Transfer Laboratory

The lab facilitates the students to understand the fundamental concepts of interphase Mass Transfer. Experimental studies equip the students with the necessary input for the design/operation of complex equipment for mass transfer operations like absorption, distillation, crystallization, extraction etc. The lab also extends facilities for conducting UG projects.

Equipments:Simple Batch Distillation Setup (SS), Steam Distillation Setup (SS), Packed Bed Column, Liquid-Liquid Extraction, Vacuum Dryer, Ion Exchange Column, Rotary Dryer, Tray Dryer, Rotating Disc Contactor, Muffle Furnace

Process Control Laboratory

Process Control Laboratory has been established to demonstrate the control of parameters like temperature, pressure, flow, level, and pH in industry. It also illustrates the function of basic controller modes (ON/OFF, P, PI, and PID) and working principle of various control valves, etc.

Equipments:Level Controller with Two Tank Interacting and Non-Interacting Tank system, Temperature controller, Pressure Controller, Flow Controller, Control Valve Trainer, On-off, Proportional & Integral Controller, Air Compressor

Technical Analysis Laboratory

The Lab is facilitated with instruments to provide the practical knowledge on Inorganic, Organic, and Physical Chemistry. Educate students to design and create environmentally benign chemical processes as well as to inculcate the practice of green technologies to develop sustainable Chemical Systems. This laboratory is associated with research components to help student and research scholars to address critical issues pertaining to environmental sustainability.

Equipments:Muffle Furnace, Electronic Balance, Hot Air Oven, Wash Water Bottle, Graduated cylinder, Thermometer, Bunsen burner, Heating Mantle, Cloud point apparatus, Flash & Fire point apparatus, Aniline point apparatus, Pour point apparatus, Cloud point apparatus

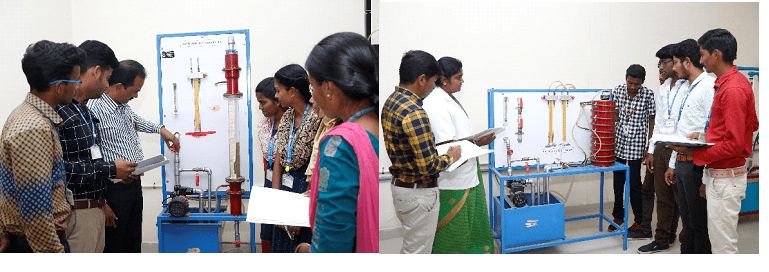

Chemical Reaction Engineering Laboratory

The lab aims to provide necessary practical knowledge on technical inputs like rate of reactions under different thermodynamic and reactor conditions necessary for the optimum design of a reactor. Experiments related to chemical kinetics and operation of batch and continuous reactors are conducted in the lab.

Equipments:Isothermal Batch Reactor, Plug-Flow Tubular Reactor, Continuous stirred Tank reactor, Packed bed reactor, Combined flow reactor