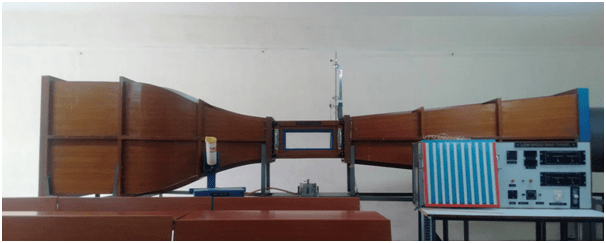

AERODYNAMICS LABORATORY

The Aerodynamics Laboratory is the state of the art in the department of Aeronautical Engineering which provides good practical knowledge on Aerodynamics. Using the facilities in the laboratories, the aerodynamics experiments on various models such as two dimensional airplane wing, circular cylinder, sphere, automobile models can be conducted. Wind tunnel and water channel facilities can be used to conduct experiments for different flow conditions. Unique subsonic wind tunnel facility of test section 600mmx600mm with test section speed of 70m/s is available in the laboratory.. After completion of this laboratory, student will be able to demonstrate experiments on two dimensional models. This laboratory would be helpful to enhance the knowledge of a student in the field of Aerodynamics.

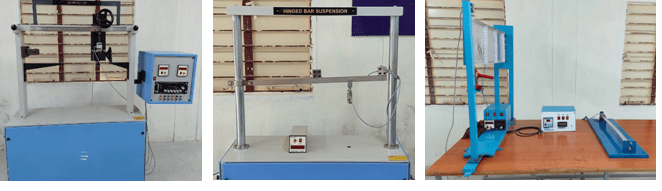

AIRCRAFT STRUCTURES LABORATORY

The objective of conducting the aircraft structures laboratory is to make the students understand the various principles involved in the aircraft structures. The laboratory is equipped with cantilever beam setup, wagner beam, vibration of beam and photoelastic technique. Student will be able to know the load distribution in the structural members and causes for deformation produced in a structural component. This will immensely help the students to enrich their knowledge in the design of various aircraft structural components, namely, wing fuselage, landing gear, control surfaces etc.

PROPULSION LABORATORY

This Laboratory is intended to teach the basics of Aircraft Propulsion, Heat transfer, Combustion and Compressible flow in various components of Gas Turbine to the Pre-final year students of Department of Aeronautical Engineering. Heat transfer studies fulfill the students’ understanding about the relation between heat transfer and engine operation and how they are implemented in the engine components.

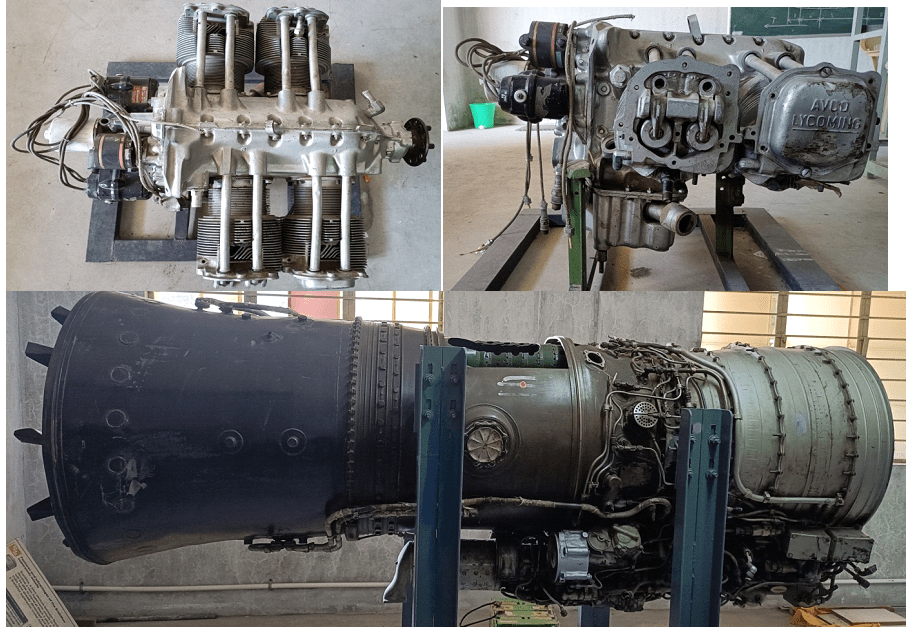

AERO ENGINE REPAIR AND MAINTENANCE LABORATORY

An engine is the heart of any aircraft. Knowing its various components, its working principles, repair and maintenance practices is of utmost importance to an aeronautical engineer. Throwing light into this fact, the aeronautical engineering department is equipped with an Aero-Engine Repair and Maintenance Laboratory. This Lab is equipped with a piston engine and a jet engine. Practical knowledge of aero-engine repair and maintenance is imparted to the students by making them physically dismantle, inspect and assemble the various components/units such as aero-engine piston, cylinder, carburettor, oil filter, exhaust unit and intake guide vanes of the piston engine

AIRCRAFT SYSTEMS LABORATORY

Students will able to learn various aircraft system and its operations, jacking up procedures and other activities. With the Cessna aircraft students will also know the functions of cockpit equipment’s.

UAV SYSTEMS LABORATORY

The Unmanned Aerial Vehicles Systems Laboratory (UAVS Laboratory) at the department of Aeronautical Engineering is developed to establish a state-of-the-art research infrastructure to support outstanding research and education in the advancement and application of this Unmanned Technology. The UAV SYSTEMS laboratory aims in nurturing young talents by bringing in multirotor & fixed wing UAV development and real-world flight testing experiences at the undergraduate and postgraduate level courses as well as working on societal-application based research projects. The UAV Laboratory encompasses work spaces with basic infrastructure for the fabrication of small UAVs, UAV system integration and laboratory as well as field tests.

Hexacopter with 1080 HD camera, transmitter and receiver with autopilot, 7 inch ground display and control unit & GPS